Repair/Refurbish Services

Gosemi Engineering can help with refurbishing and repairing your existing products.

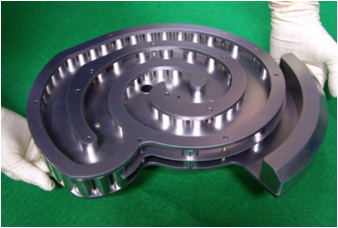

Magnets

Common Magnet Failures:

Common Magnet Failures:

- Lost Magnetization force (Gauss) by built up the oxidization

- Mechanical damages on the surface

- Uniformity Failure (<4%)

Magnet Refurbishing Process

- Inspection of Gauss

- Disassembly & Polishing

- 1st Re-magnetization or Damaged Parts Change

- Gauss measurement after assembly

- Gauss control & Gauss distribution check

- 2nd Magnetization (Gaussian Supplementary if needed)

- Final Test: Gauss Test, Uniformity Test

MCA Heaters

- Surface treatment and reconditioning

- Flatness to a like-new condition

- Treatment of luminosity to a like-new condition

- Welding technology between SUS and ALN plates

- Heater terminal welding technology

- Helium line welding technology

- All tests performed: Leak Test, Temperature Test, Uniformity Test, Chucking Test,

etc

- Life-time: Bellows and surface conditions the same as original new condition