About Gosemi Engineering

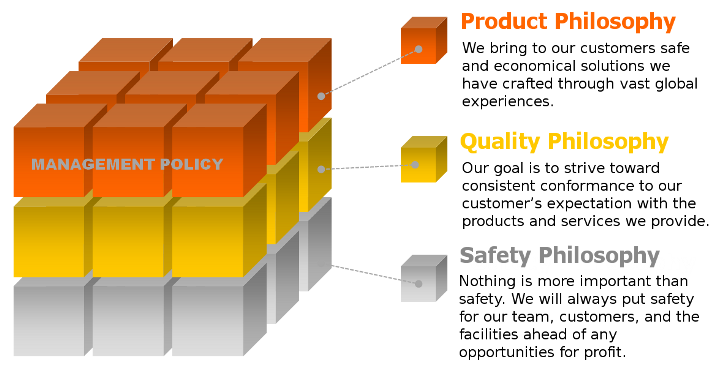

GSE Management Policy

Customer Care Policy

We believe in forging long term relationships with our customers by providing cost

effective maintenance solutions that are optimized for the specific needs of the

customer.

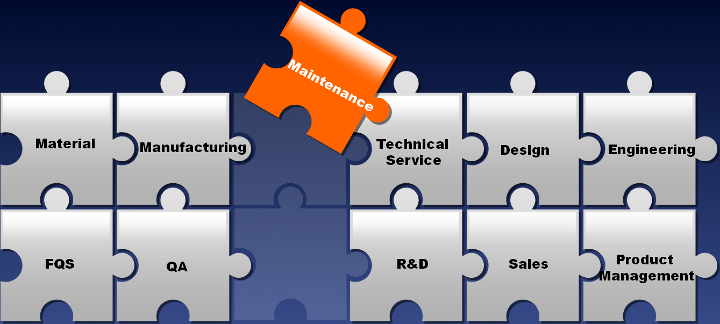

GSE Management System

GSE Experience

- POU Abatement System Maintenance Experience at SAS

- POU Development

- Facility Management

- PLC Program Specialist

- Circuit Board Repair

- Gas Abatement System (POU)

- Photo Engineering

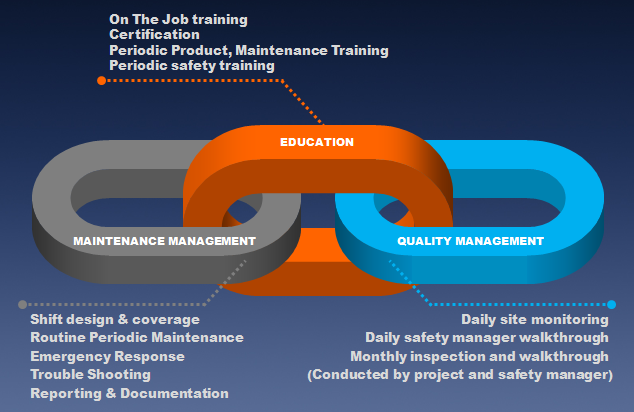

GSE Maintence Strategy

GSE Local Maintence Service

Utility Infrastructure Installation

GSE has expertise in fabrication and installation of high purity piping systems

and exhaust lines for semiconductor manufacturing facilities.

Scope of Service:

- Hook-up service for new tool installation; tool movement

- Utility line installation: DI Water, Nitrogen, PCW, etc.

- Ultra high purity chemical delivery system installation

- Ultra high purity gas delivery system installation

- Exhaust system design and installation

Sub Fab Maintenance Service

GSE Provides a full range of maintenance services for various components of the

sub fab vacuum and exhaust systems.

Scope of Service:

- Dry pump exhaust line periodic maintenance

- Hot N2 system installation and maintenance program

- Gate Valve maintenance service

- Powder Trap installation and periodic Maintenance

- Supply sub fab materials such as fittings, valves, and gauges

Part & Repair & System Service

GSE Provides a full range of most part services to semiconductor manufacturing facilities.

Scope of Service:

We handle anything from a simple repairs to contracted on-site maintenance services

and parts.

Through our innovative maintenance solutions our customers can:

- LOWER THE COST OF OWNERSHIP OF SYSTEMS

- EXTEND SERVICE INTERVALS

- INCREASE MANUFACTURING TOOL UPTIME

- SAVE OVERALL MANAGEMENT COST

GSE Training System