Advanced Heating Vessel (AHV)

Description

The Ex’et issues are matters that had never fully been resolved since the rise of

the semiconductor industry. Examples of unresolved recurring issues include but

are not limited to Power Clogging, Leaks, Utility Increases, Coo Increases, and

Environmental Impacts. The initial development of Ex’et was to minimize costs while

simultaneously maximizing product effectiveness.

1. Heat jacket The methods that are currently in place causes the by-product to

accumulate inside the column.

2. ETS –Hot N2 The ETS method takes in the N2 and mixes with the by-product, immediately

matching the temperature levels, allowing a more efficient flow to be pushed out.

3. AHV- Internal Heating System The heater within facilitates in eliminating excessive

moisture which allows the by-product to pass more effectively.

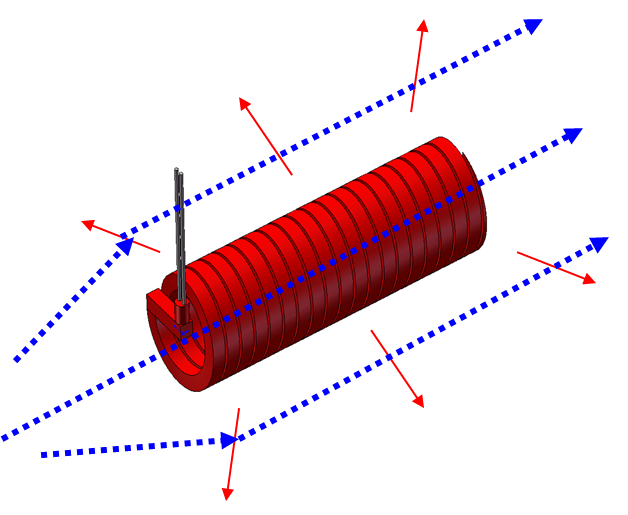

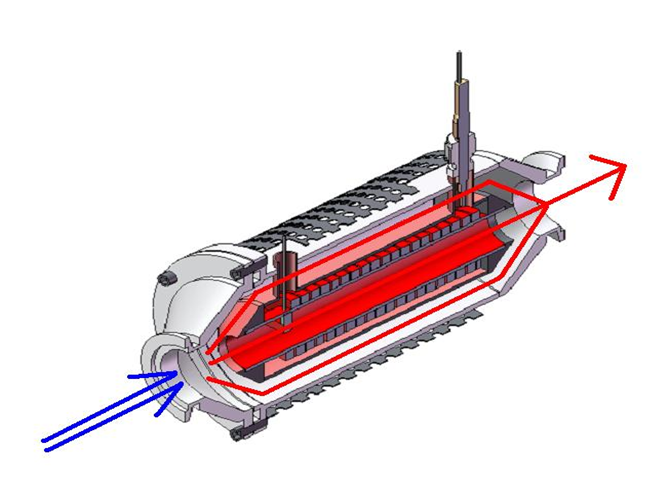

Principle

In a heated state, the Heating Chamber will take in the flow of waste gas into both

the inner and outer channels. While leveling the temperature, the heating chamber

emissions will then immediately begin to absorb the moisture from the process waste

gas. The results of the efficiency can be observed at the pipe connections. The

utilization of the Heating Chamber method will undoubtedly improve productivity

efficiency.

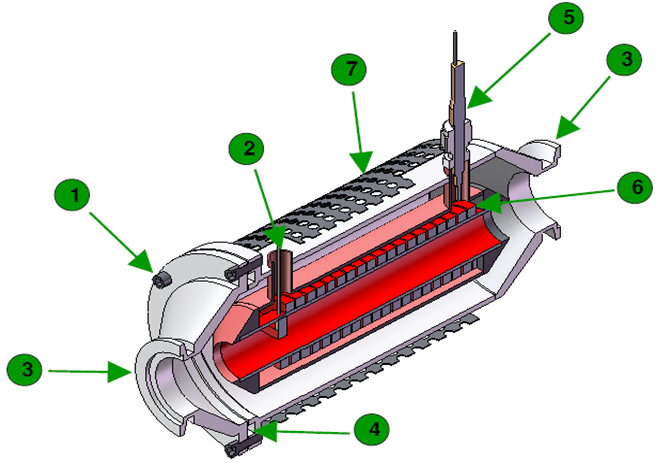

Parts Diagram

- P/M Flange Dividing Bolt - The fixation bolt for P/M and repair of the H/C

- Heater Electric Supply Port - The portion which electric supply port of heater

is inserted

- NW50(IN/OUT) - C-Clamp connecting Flange for connecting with a pipe

- O-RING - NW80

- Temp Sensor Port - Port which T/C is inserted

- Heater - Rising temperature of H/C

- Heat insulating board - Protect a burn and a fire from the emitted heat

POU Inlet Use Example